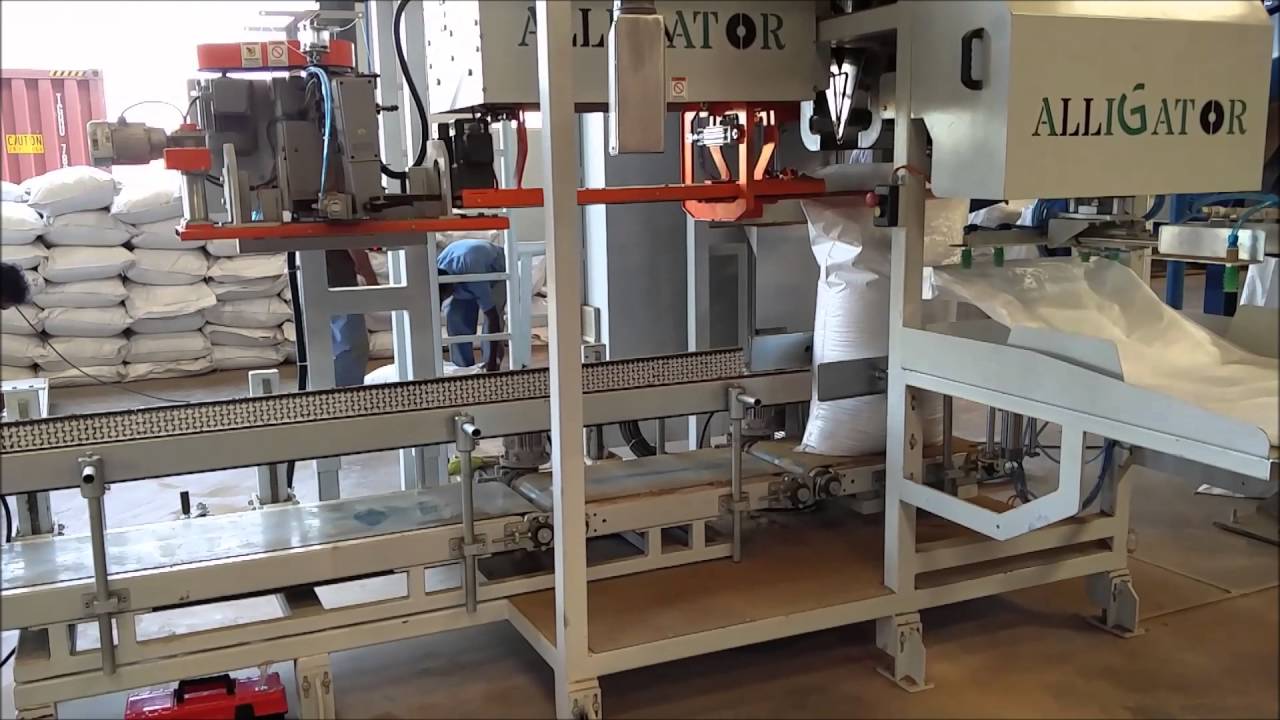

Technological advancements benefit every industry, and the packaging sector is no exception. Automatic bagging machine systems are notable innovations that help ease packaging in multiple ways. If your company has not yet adopted this technology, this post will help you make a well-informed decision.

Signs to Invest in Automatic Bagging Machine System

Are you worried about your packaging line’s inability to meet clients’ demands? If so, this could be the right time to automate. You can consider investing in the matrix bagging machine system for the following reasons.

Frequent Errors and Mistakes

Manual packing might look economical, but it often leads to mistakes affecting overall operating costs. However, an automatic system guarantees consistent quality and accurate packaging. It minimizes returns and ensures customer satisfaction, building long-term relationships.

Growing Business

Your packing business needs to gain a competitive edge and stay ahead. However, this cannot be possible if you fail to meet customers’ demands on time. Matrix bagging machine system will help you sidestep this challenge by keeping up with demand. It enhances your business’s potential for growth to avoid losing vendors and clients.

High Labor Costs

It’s important for your business to minimize expenditure and maximize deliveries. However, labor costs could weigh you down because you have to cater for salaries, insurance, and other guarantees. Besides, you may have to hire temporary workers for peak season or when your employees take time off. Fortunately, an automatic bagging system is run by one operator, helping you reduce labor costs. With proper maintenance, the machine will also give the best returns on investment.

Improved Workplace Safety

Packaging causes repetitive motion that can lead to long-term injuries to your employees. It could hurt your operations because of high turnover or incurring disability compensation costs. An automatic packaging system is one of the best ways to invest in workplace safety because it minimizes employee injuries.

Unnecessary Waste

Besides costing you more, manual labor could lead to too much waste due to inaccuracy. Your employees could overfill or damage the packaging bags, causing inconsistency in your services. Besides, you may be forced to use more materials than necessary. Matrix bagging machine system automatically packs your products, guaranteeing accuracy for minimal waste. You’ll get the highest returns on your investments in terms of cost savings.

Lengthy Changeovers

If your business produces different items, you’ll require frequent changeovers that can be time-consuming. Besides, it increases idle time for employees as they have to wait for the next product to be ready. However, automating your packaging processes eliminates the tedious and lengthy changeovers.

The solution will also be effective for simple repetitive packaging. This is especially for simple, similar-shaped packages or bags. If you have irregular-shaped or bulky packages, working with an experienced bagging machine system expert will help you find what meets your needs.

Final Word

Industrial automation is crucial for your business to decrease overhead costs and maximize productivity. Matrix bagging machine system can help you streamline your operations to meet the growing demand and gain a competitive edge.